PART III | 7 PORT DESCRIPTION

7.16.10.3 Berth criteria (Berth #2)

| DESCRIPTION | DATA |

|---|---|

| Parcel Size | 5,000 - 50,000 MT |

| Maximum SDWT (registered) | 71,000 MT |

| Minimum DWT | 5,000 MT |

| Fender Capacity | 55 ton/meter per fender pile |

| Mooring Hooks | 100 ton bean type bollard |

| Dredged draft | 12 meters BCD |

| Maximum summer draft allowed | 11 meters |

| Maximum Berthing displacement | 36,000 MT |

| Maximum Sailing displacement | 61,000 MT |

| Maximum beam | 32.5 meters |

| Minimum hatch opening required | For Bag ship: 6.5 x 6.5 meters For Bulk Ships: 5 x 5 meters |

| Max. Freeboard (water Line to Hatch Coaming) on arrival 15 meters | |

| Minimum Height of hold should not be less than 3 meters. | |

| Maximum depth of hold not to exceed 15 meters | |

| Position Lat. / Long | Lat. 24° 09.217’ N, Long. 052° 052 44.035’ E. |

| Direction of the berth | 350°/170°. |

7.16.10.4 Ammonia Vessels

No vapor returns facility at shore.

No venting of vapor when ship alongside Jetty.

Ship should come with coolant at temp about minus 33 deg. C or below.

Sample will be collected from ship's tanks on arrival to analyze for Ammonia purity. Therefore, vessel to arrive with sufficient pressure in tanks to collect samples.

Vessel will be passed for loading only when Ammonia purity is> 99% by volume.

| DESCRIPTION | DATA |

|---|---|

| Maximum DWT | 25,000 MT |

| Minimum DWT | 5,000 MT |

| Fender capacity | 55 ton/ meter per fender pile |

| Mooring hooks | 9 nos. 100-ton quick release Type hooks & others 100-ton Bean type bollards |

| Dredged draft | 12 Meters below CD. |

| Maximum summer draft allowed | 11 Meters below CD. |

| Maximum displacement | 61,000 MT. |

| Height of Jetty | 7.4 Meters above CD. |

| Maximum free board of ship on arrival | 13 Meters above CD. |

| Loading arm height | 22 meters above CD |

| Horizontal movement of arm | 5 meters |

| Sideways movement of arm | 3 meters |

| Manifold size | 8’’ – 300# |

7.16.10.5 Ethylene Vessels

| DESCRIPTION | DATA |

|---|---|

| Maximum DWT | 25,000 MT |

| Minimum DWT | 5,000 MT |

| Fender capacity | 55 ton/ meter per fender pile |

| Mooring hooks | 9 nos. 100-ton quick release Type hooks & others 100-ton Bean type bollards |

| Dredged draft | 12 Meters below CD. |

| Maximum summer draft allowed | 11 Meters below CD. |

| Maximum displacement | 61,000 MT. |

| Height of Jetty | 7.4 Meters above CD. |

| Maximum free board of ship on arrival | 13 Meters above CD. |

| Loading arm height | 22 meters above CD |

| Horizontal movement of arm | 5 meters |

| Sideways movement of arm | 3 meters |

| Manifold size | 8’’ – 150# |

7.16.11 Abu Dhabi Polymers Company Ltd (BOROUGE - Polyethylene)

7.16.11.1 General

The BOROUGE Polyethylene Terminal at Ruwais is situated immediately to the East of Ruwais small boat Harbor, with a protrusion at the western end to accommodate Ro-Ro / Gearless Container feeder/Ocean going vessels. The Ro-Ro ramp is a class B ramp in accordance with BSMA 97. The Container feeder terminal is designed to accommodate a range of vessels with the following characteristics: The container berths are equipped with two STS cranes each on berths 1 & 2 & four mobile RTG cranes each on berths 3 & 4 respectively.

7.16.11.2 Berth Criteria / Parameters

| PARAMETERS | B-01/02 | B-03 |

|---|---|---|

| Max. DWT | 20,000 MT | 38,000 MT |

| Maximum Displacement | 27,000 MT | 50,000 MT |

| Container capacity | 1100 - 1800 TEU | 2600 - 3000 TEU |

| Max. Berth Length | 384 m | 500 |

| Max. vessel length | 180 m | 223 m |

| Maximum Beam Accepted | 27 m (11 rows) | 32 m (13 rows) |

| Max. water depth alongside | 10.5 m | 13.5 m |

| Max. Draft | 9.0 m | 12.00m |

| Alongside | Port side | Starboard side |

| Bow Flare angle | 20° | 20° |

| Turning Circle available | 530 m | 530 m |

| Depth in the channel | 13.5 m | 13.5 m |

| Approach channel width | 160 m | 160 m |

| Max Approach Velocity | 0.18m/s | 0.18m/s |

| Position Lat. / Long (centreline) | 24° 08.12’ N, 052° 45.05’ E | 24° 08’ 02.05’’ N. 0520 45’ 22.96’’ E |

| Container berth | 1 | 2 |

| Direction of the berth | 295°/115° | 000° / 180° |

7.16.11.3 Mooring

The design is made on the basis that fenders on the quay wall absorb all the energy of berthing vessels. The fender system is designed to accommodate vessels as per the berth criteria given above.

Bollards have a maximum Mooring Load capacity of 60 tons.

For stability consideration, berthing and mooring forces are based on a wind speed of 110 km/h.

A Gangway shall be provided by the ship’s personnel. A warning shall be placed adjacent to the gangway prohibiting the entrance of unauthorized persons, prohibiting smoking and the use of open flames.

The approach channel is marked with 13 numbers of buoys as per IALA standards.

7.16.11.4 Communication

Communication between ship crew and BOROUGE Terminal personnel will be established by means of portable radios . This equipment will be according to BOROUGE safety standards and must be tested every time prior to starting the loading / unloading operation.

7.16.11.5 Un-berthing

The ship should leave the terminal immediately after the completion of loading and documentation. Before informing the pilot for un-berthing, it is the responsibility of the Master to ensure that all connections between the ship and shore are removed and that she is ready to sail.

7.16.11.6 Incident Reporting

The master of the vessel, for the time the vessel is alongside the BOROUGE terminal, is responsible for reporting all incidents on board the ship immediately to Petroleum Ports Authority through Port Control and BOROUGE Safety Department.

7.16.11.7 Safety

The ship’s safety equipment shall be ready prior to starting any loading or unloading operation. This will be verified by completion of the Ro-Ro/Container feeder ship/shore safety checklist.

7.16.12 ADNOC Gas Processing (formerly GASCO) - Ruwais LNG terminal

7.16.12.1 General

The Ruwais LNG Terminal (RLNGT) is situated at the ADNOC Gas Processing Terminal No. 1 Berth No. 2. The centerline of the terminal is located in position Lat 24° 08.90’ N, Long 052° 44.33’ E. The orientation of the berthing line is approximately 115 ° /295 ° .

Sulphur Berth 2 has been converted for use as a receiving terminal for LNG. Some of the modifications made were the addition of mooring dolphin No. 5 to the SE of terminal, and the replacement of the Quick Release Hooks (QRH) x 100 tonnes x 3 each on the existing mooring dolphins (5 nos).

A new loading platform consisting of the HP Gas Marine Loading Arm (MLA) package, the jetty emergency shutdown (ESD) skid, a firefighting monitor, and associated piping was constructed.

Additional components include:

- A gangway from berthing dolphin No. 2

- The access trestle and pipe rack crossing

- A new equipment room and/or control room

- The gas metering skid

- Four water bath heaters

- The vent stacks

- The velocity and pressure control valves

- Gas Receiving Facility (GRF) ESD skid

- Two-kilometer pipeline to the receiving point and tie in to the ADNOC Gas Processing Network

- A Floating Storage and Regasification Unit (FSRU) is permanently moored at Ruwais LNG Terminal and will receive supplies of liquefied natural gas (LNG) via conventional LNG carriers (LNGCs).

7.16.12.2 Berth Layout

The berth consists of four (4) breasting dolphins. The two (2) end dolphins are equipped with 4 (four) quick release hooks assemblies and the center two only have a bollard (non-functional) facility. In addition, there are Five (5) mooring dolphins, three (3) at fore & two at aft ends, each of which are equipped with three (3) x 100 tonnes quick release hooks assemblies.

The breasting/mooring dolphins are supported by 5 (Five) piles.

Eight (8) separate structural steel walkways connect various areas of this offshore marine facility.

One structural steel semi arc ship loader outrigger beam for loading granulated sulphur is parked in one corner.

The FSRU shall be moored starboard side to the jetty.

The Ruwais LNG Terminal has been designed to receive in addition to the FSRU, an LNGCs sized up to 173,000 m3.

7.16.12.3 LNG Transfer

The LNG cargoes are delivered to the FSRU via ship-to-ship (STS) transfer operations with LNGC arranged in a double banked arrangement. The FSRU is equipped with STS arrangement consisting of;

- Eight (8) cryogenic 8” hoses allowing transfer at a maximum rate of 5,000 m ³ per hour

- Five (5) primary Yokohama Fenders of size 4.5 x 9 mtrs,

- Two (2) secondary (baby) Yokohama fenders of size 3.0 m x 1.5 m.

The fenders are placed on the port side of the FSRU. The primary fender string and both baby fenders shall be secured with their dedicated wires to bollards on the FSRU fore and aft deck areas. The safety wire shall be made off to a mooring bit.

The secondary (baby) fenders shall be one (1) placed forward and one (1) placed aft at the upper and outer ends of the parallel mid-body, suspended approximately 1.5 m below the main deck.

As a general rule, LNG transfer operations by STS may take place in a sea state up to a maximum wave height of 2.0 m.

7.16.12.4 Operational Limitations

Mooring and cargo transfer operations at the RLNGT are weather determinant. Weather forecasts and prevailing conditions should be duly evaluated in regard to suitability of conditions for mooring and cargo transfer operations.

The suitability of weather conditions for mooring and remaining moored at the RLNGT reside with the PPA in consultation with the vessels Master.

Departure of the FSRU is at the discretion of the Petroleum Ports Authority / FSRU Master.

7.16.12.5 Mooring Preparation

The FSRU shall moor to the RLNGT Jetty under the direction of the Pilot in accordance with the (pre)approved mooring line configuration.

Mooring lines shall be pre-tensioned with consideration for existing and anticipated wind conditions and the stage of the tide. Pre-tensioning shall be approximately ten (10) tons on all lines.

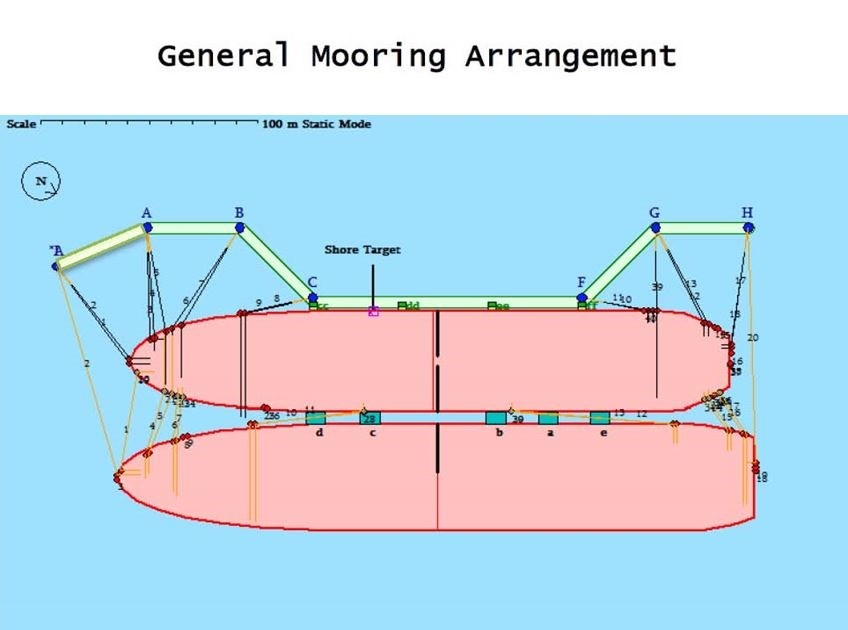

7.16.12.6 FSRU Mooring Layout Description

The LNG Terminal jetty mooring arrangement is designed to moor the FSRU by means of sixteen (16) lines. Two (2) quadruple quick release hooks (QRH) are located on berthing dolphins (BD) 1 and 4. Even though there are four hooks. Five (5) MDs, each fitted with triple quick release hooks, are located three (3) forward and two (2) aft in way of the vessel bow and stern locations. These hooks can all be used.

Mooring line loads from the FSRU and the Jetty Control Room (JCR). The actuation of the QRH function is controlled locally and from the JCR.

The four berthing dolphins are equipped with SCN1600 (E2.8) super-cone fenders from Trelleborg.

7.16.12.7 Access and Gangways

The RLNGT Operations Team shall control the lifting of the jetty gangway across the vessels handrail and position the gangway ladder on the appropriate vessel ‘strongpoint’ under the direction of the responsible officer from the FSRU Excelerate.

RLNG Staff is responsible for the maintenance and proper operation of the gangway.

The FSRU staff is responsible for access control in accordance with the ISPS Code and company security procedures.

There will be no crew changes nor shore visits for personnel on the LNGC.

The transfer of personnel between the FSRU and the LNGC shall be arranged by means of “Safe Access” via an approved type Personnel Transfer Arrangement.

Only personnel essential for operations shall be transferred between the vessels. Essential persons include, but are not limited to:

The FSRU staff will attend STS pre-transfer meeting onboard of the LNGC.

ADNOC Gas Processing Marine will receive documentation on behalf of cargo Interests / receivers, the LNGC agent and the nominated cargo surveyor.

7.16.11.8 Parameters

| LNG TERMINAL PARAMETERS | |

|---|---|

| Maximum Displacement | 132,000 T |

| Maximum berth Length, | 320 M |

| Maximum LOA (FSRU) | 300 |

| Maximum Dead weight | 84,000 T |

| Max. Water depth alongside | 15 M |

| Max Draft | 13.65 M |

| Turning Basin at BCT No. 6 Buoy. | 700 M |

| BCT Channel/Turning Basin Depth | 14.5 M |

| Distance B/W BCT No. 6 Buoy & RLNGT | 600 M |

| Distance B/W BCT No. 8 Buoy & RLNGT | 400 M |

| Distance B/W BCT No. 8 /10 Buoy Line Joining & LNGC | 140 M |

| Parallel Body Length Terminal | 80 M |

| Channel Length From Centre line of BCT No. 1 & 2 Buoys Till RLNGT | 1400 M |

| FSRU Max. capacity | 138000 M3 |

| LNGC Max. capacity | 173000 M3 |

7.16.13 Service Harbour (RIASH)

7.16.13.1 Location and Berths

Ruwais Service Harbour, named as Ruwais Industrial Area Services Harbour (RIASH) consists of four berths and one Ro – Ro berth. It is situated to the East of the Ruwais Petroleum Complex.

7.16.13.2 Depths / drafts

Vessels and barges with a maximum draft of less than 6.0 meters may enter and lie safely alongside.

7.16.13.3 Usage

ADNOC Logistics & Services /OSRC is using these berths for port operations/pollution control. Jetty No. 4 is in use for OPCOs project heavy lifts operations.

7.16.13.4 VTIS

The VTIS station is installed in the Ruwais Port Control Room.

7.16.13.5 Harbour Information

| NO. | ITEM | DESCRIPTION |

|---|---|---|

| 1 | Port Control Room/Port Working Hrs | Continuous Watch On Vhf Channel 16 /9/21 – 24 Hrs |

| 2 | Port Entry Restrictions | ADNOC Vetting Inspection approval / PPA Craft Entry permit to be obtained prior entering port’s limits |

| 3 | Anchorage Positions | 3 NM West of Ghasha RACON or 1.5 NM NE of East Ghasha Buoy |

| 4 | Restrictions | Berthing/un-berthing and transiting channel will be carried out only during daylight hours |

| 5 | Availability of towage service | Port’s tugs are used for berthing/un-berthing & passive escorting in the channel |

| 6 | Availability of cargo Gears/Cranes/Stevedores | Not Available – Harbour users contractors to arrange |

| 7 | Port Charges – RoRo vessel | As per Port Tariff |

| 8 | Port Charges – Barge under Tow | As per Port Tariff |

7.16.13.6 Berth Information and Limitations

| NO. | ITEM | RO-RO BERTH | HEAVY LIFT BERTH |

|---|---|---|---|

| 1 | Tidal Range | 1.00 m / Tides are diurnal | 1.00 m / Tides are diurnal |

| 1 | Density | Summer 1028-Winter 1033 | Summer 1028-Winter 1033 |

| 3 | Borouge Channel Depth/Width | 13.50 m / 160.00 m | 13.50 m / 160.00 m |

| 4 | Number of Berth for cargo operation | One Berth | One Berth |

| 5 | Berth length | 73.5 m | 91.4 m |

| 6 | Water Depth | 7.0 m | 7.0 m |

| 7 | Displacement | 15,000 MT | 15,000 TM |

| 8 | Berth Width | 41 m | - |

| 9 | Ramp Length | 43 m | - |

| 10 | Bollard capacity | 50 MT | 50 MT / 100 MT(Two end dolphins) |

| 11 | Berth Height | 2.00 m. All levels measured to Jebel Dhanna chart datum (JEBEL DHANNA CHART DATUM) which is 0.23 m above Admiralty chart datum (ACD). Boat Ramp/1.50 m | 3.75 m. All levels measured to Jebel Dhanna chart datum (JEBEL DHANNA CHART DATUM) which is 0.23 m above Admiralty chart datum (ACD) |

| 12 | Max Draft Permissible | 6.0 m | 6.0 m |

| 13 | Max LOA Permissible | 70 m | 91 m |

| 14 | Max Breadth Permissible | 25 m | 30 m |

| 15 | Max Permissible Displacement | 15,000 MT | 15,000 MT |

| 16 | Berth Load Bearing Capacity | 30 kn/m2 | 100 kn/m2 |

| 17 | Asphalt Road Load Capacity | 100 kn/m2 | 100 kn/m2 |

7.16.14 Sir Baniyas Cruise Terminal

Abu Dhabi Ports has developed and commissioned a Cruise terminal on the SE corner of Sir Baniyas Island. The terminal consists of two berths, Berth-1 (NE berth) and Bert-2 (SW Berth). The parameters for both berths are as per below:

| Parameter | Berth 1 - NE Berth | Berth 2 - SW Berth | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Maximum Displacement | 100,000 MT | 100,000 MT | |||||||||||||

| Maximum Berth Length | 110 m continuous central platform (400m with dolphins) | 110 m continuous central platform (400m with dolphins) | |||||||||||||

| Maximum Allowed Length Over All (LOA) | 360m | 360m (restricted to 6.6 meters draft) | |||||||||||||

| Minimum Allowed Length Over All (LOA) | 181m. For vessels with LOA less than 181m, the vessel owner/operator shall be required to make their own determination to confirm that the berth layout and configuration is suitable for the safe berthing and mooring of their specific vessel. | 181m.For vessels with LOA less than 181m, the vessel owner/operator shall be required to make their own determination to confirm that the berth layout and configuration is suitable for the safe berthing and mooring of their specific vessel. | |||||||||||||

| Maximum Beam | 47m | 47m | |||||||||||||

| Minimum water depth alongside | -12.5 m New Abu Dhabi Datum [≈ -11.4 m Chart Datum] | -9.0 m New Abu Dhabi Datum [≈ -7.9 m Chart Datum] | |||||||||||||

| Maximum Draft Allowed | 9.4m | 6.6m | |||||||||||||

| Turning Basin Diameter | 700m | 700m | |||||||||||||

| Parallel Body Length Terminal | 110m continuous central platform (400m with dolphins) | 110m continuous central platform (400m with dolphins) | |||||||||||||

| Fenders -Type -Width/Diameter-Number/Distance between | Fenders: - CSS 2000 G1.8 - 2.2m - 22.5 m c/c on main platform & one (1) per breasting dolphin | Fenders: - CSS 2000 G1.8 - 2.2m - 22.5 m c/c on main platform & one (1) per breasting dolphin | |||||||||||||

| Bollards-Safe working load (SWL)-Distance between | Varies: - 171t SWL on Breasting Dolphins & 200t SWL on Mooring Dolphins - 22.5 m c/c on main platform; two (2) per breasting dolphin & three (3) per mooring dolphin | Varies: - 171t SWL on Breasting Dolphins & 200t SWL on Mooring Dolphins - 22.5 m c/c on main platform; two (2) per breasting dolphin & three (3) per mooring dolphin | |||||||||||||

| Direction of berth (heading) | 145°/325° | 145°/325° | |||||||||||||

| Position (central on main platform at fender line) | 24.287120°/052.640590° | 24.287022°/052.640431° | |||||||||||||

| Operational Limitations | |||||||||||||||

| |||||||||||||||

7.17 WEATHER AND TIDAL INFORMATION

7.17.1 Climate

The cool winter season extends over November to February with mean daily maximum temperatures of 25 to 30° C and night temperatures of 10 to 15° C. The lowest recorded temperature being 4° C. Ground frost can occur inland. The hot summer season extends over May to September with maximum day temperatures between 40 to 45°C, the highest recorded being 48° C. Night temperatures are about 20 to 25° C. Therefore, it is important that during the hot season the temperature within the visiting tankers accommodation shall not exceed 25°C. Relative humidity is high throughout the year averaging between 50 to 60 per cent by day and 75 to 80 per cent by night. Heavy dew may be experienced throughout the year. Rainfall is usually associated with thunderstorms which are prevalent from November to May giving a total annual rainfall of 10 to 50 mm. Rain is rare during the remaining months while in some years there is none at all. Throughout the year the prevailing winds are from the West to North North East sector. They are strongest between November and April when they occasionally reach gale force. Gusts of up to 50 knots have been recorded (April) and a 24-hour mean wind speed of 32 knots from the North-West is on record (January). The shamal or strong North West wind may blow for periods of up to three days and raise a rough sea with waves up to 4.5 meters. Land and sea breeze is experienced throughout the year. Visibility is 10 nautical miles for 70 per cent of the time and less than 2 nautical miles up to 5 per cent on occasions due to dust, haze or radiation fog. Fog can occur during any month of the year but is most frequent in winter. Normally it develops during the night and early morning and clears by 10.00 hours. Usually the fog banks drift to seaward towards Sir Baniyas Island. Sea temperatures at 3 meters depth, range from 20°C (in winter), to 32° C (in summer). During the summer the 15 meters depth temperature is only a degree or so lower than that at the surface.

7.17.2 Wind and Tide

Prevailing winds are from the North West. However there are occasions, when sudden gusts of local ‘Shamal’ winds may be experienced where winds can go as high as 50kts. or higher. Rise of tide can be up to 2 meters, but the usual variation is 1 meter. The highest average, spring high tide is about 2.0 meters above chart datum. The lowest average, neap high tide is 1.0 meter above chart datum.

7.17.3 Tidal Streams/ Currents

In the outer approaches to Ruwais, tidal streams would appear to attain a maximum of 1 knot while 1.7 knots may be encountered in the channel NE of Jazirat Sir Baniyas.

_Tidal currents in the area of the berths seldom exceed 0.4 knots. Tidal current is generally along a NNW - SSE axis.

_Tides are generally diurnal; winds from NE and NW may cause an increase up to 0.6 meters in the height of the tide. Max. Tidal rise is 1.2 m.